In an constantly changing world in which technology and innovation propel progress, the need for dependable and robust connections is paramount. This is especially true in industries in which environmental factors can jeopardize the functionality and safety of electronic systems. Hermetic sealed connectors emerge as a key solution to this challenge, providing protection against moisture, dust, and gas infiltration. Understanding how these connectors work is essential for engineers and designers who strive to guarantee the longevity and reliability of their applications.

Hermetic sealed connectors are engineered to create a barrier that prevents contaminants from entering vulnerable electronic components. They achieve this through sophisticated sealing techniques, often utilizing glass-to-metal or metal-to-metal seals that establish an airtight environment. This unique feature not just enhances the durability of the connectors but also enables them to perform effectively in extreme conditions, making them essential in aerospace, military, medical, and other high-stakes fields. By delving into the mechanics of these connectors, we can appreciate the sophisticated engineering that underpins their function and the vital role they play in safeguarding critical systems.

What do we mean by Hermetic Connectors?

Hermetic sealed connectors represent specific power connectors designed to provide a safe and reliable seal against environmental elements such as humidity, dust, and gases. Such connectors find application in situations where harsh environmental exposure can lead to failure, guaranteeing the integrity of the electrical connections for extended periods. The hermetic seal prevents any impurities from entering the connector, which is crucial in demanding environments including outer space, marine-grade and military environments.

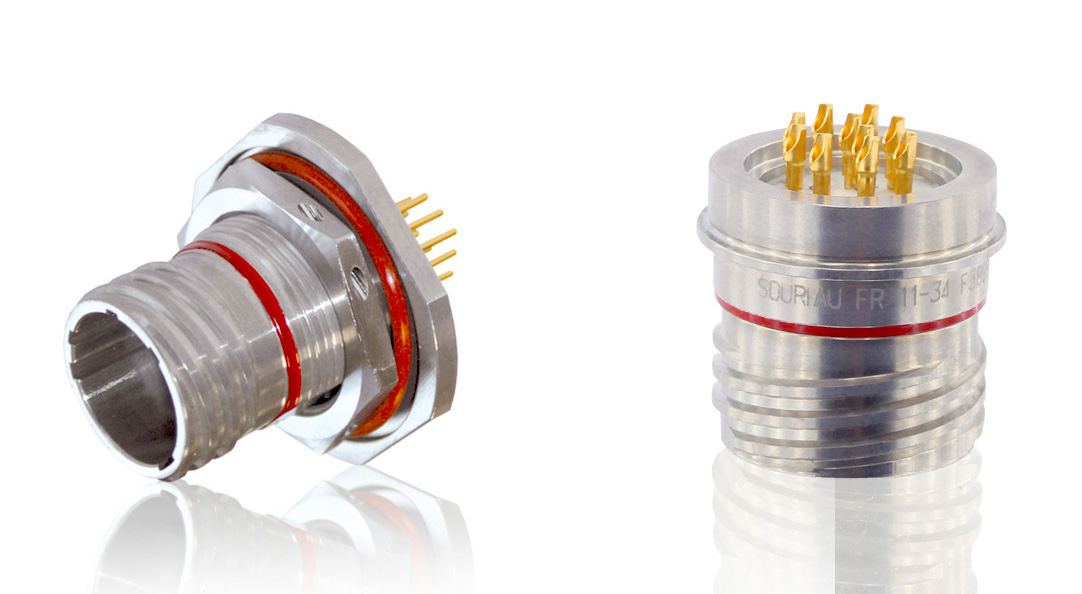

The construction of these connectors typically entails materials that can withstand severe heat & pressures. Specialized glass, aluminum, and special polymer blends are commonly used to construct a durable outer casing that can resist harsh conditions. The sealing mechanism commonly uses methods such as welding or epoxy bonding, guaranteeing that the internal parts stay safe from environmental influences. This level of engineering allows hermetic connectors to deliver efficiency and trustworthiness in situations where regular connectors might break down.

Besides their safeguarding features, hermetically sealed connectors are manufactured for user-friendliness & installation. They often feature robust locking mechanisms to guarantee a secure connection reducing the risk of accidental disconnection. The variety of designs available allows them to be used in several fields, be it for power delivery or data transfer. In conclusion, hermetically sealed connectors are crucial in safeguarding electrical connections, enhancing the durability and performance of complex systems.

Applications and Advantages

Hermetic sealed connectors are commonly utilized in various industries due to their ability to provide a dependable barrier against surrounding conditions such as humidity, contaminants, and extreme temperatures. In space technology, for illustration, these connectors ensure that delicate electronic components remain operational even in severe environments beyond the Earth’s sky. Their trustworthy performance under pressure variations and temperature extremes makes them appropriate for both orbital and aircraft systems.

In the medical industry, hermetic sealed connectors play a key role in ensuring the security and efficacy of devices used in diagnostics and treatment. By stopping any contamination from outside influences, these connectors help maintain clean conditions necessary for medical equipment, minimizing the risk of infections and breakdown. Their application into devices such as insertable sensors and life-support systems showcases their critical importance in patient care and safety.

The automotive sector also derives significant advantages from hermetic sealed connectors, particularly in electrical and hybrid vehicles. These connectors shield vital electrical connections from exposure to harmful environmental conditions, such as moisture and corrosive substances, thereby enhancing the longevity and dependability of the vehicle's electrical systems. As the market moves toward increased automation and connectivity, hermetic sealed connectors will persist in an important role in ensuring that complex electronic systems function correctly and efficiently.

Emerging Innovations in Sealed Sealing Technology

As innovation continues to evolve, the need for hermetic sealed hermetic interfaces is increasing across various industries, particularly in aerospace, medical, and telecommunications. One notable trend is the creation of substances that enhance longevity and reliability in extreme environments. Innovations in synthetic materials and blended materials are permitting producers to create sealed seals that offer outstanding protection against humidity, dust, and chemical exposure, ensuring maximum performance regardless of the most severe conditions.

Another movement is the integration of innovative manufacturing techniques such as 3D printing and exact machining. These technologies allow for the fabrication of complex shapes that were once difficult to attain, improving the design and functionality of hermetic connectors. This adaptability not only boosts the seal capabilities but also lowers production costs and delivery times, making hermetic sealing available to a wider range of applications.

Additionally, the growing stress on miniaturization in electronics is influencing hermetic sealing methods. Designers are aiming to create more compact, lighter, and optimized hermetic interfaces without compromising on performance. This inclination towards compact forms is driving innovation in both connector design and the sealing methods, paving the way for more flexible uses in emerging fields like the Internet of Things and wearables.